Industrial Dust, Air Pollution and related Occupational Diseases – Nuisance to be controlled for improvement of general environment, safety and health standard:

1.0. Introduction - Air pollution is the presence of high concentration of contamination, dust, smokes etc., in the general body of air man breaths. Dust is defined as particulate matter as “any airborne finely divided solid or liquid material with a diameter smaller than 100 micrometers.” Dust and smoke are the two major components of particulate matter. Car emissions, chemicals from factories, dust, pollen and mold spores may be suspended as particles. Ozone, a gas, is a major part of air pollution in cities. When ozone forms air pollution, it’s also called smog. These materials come from various sources, such as, various industrial processes, paved and unpaved roadways, construction and demolition sites, parking lots, storage piles, handling and transfer of materials, and open areas. Some air pollutants are poisonous. Inhaling them can increase the chances of health problems. In fact, dust when inhaled can increase breathing problems, damage lung tissue, and aggravate existing health problems. In addition to health concerns, dust generated from various activities can reduce visibility, resulting in accidents. Therefore, every federal Govt. has stringent regulations which require prevention, reduction and/or mitigation of dust emissions.

Thus, prime sources of air pollution are the industrial activities or processes releasing large quantity of pollutants in the atmosphere. These pollutants are mainly:

(a) Smoke comes out from various industries like, power plants, chemical plants, other manufacturing facilities, motor vehicles, etc.;

(b) Burning of wood, coal in furnaces and incinerators;

(c) Gaseous pollutants from Oil refining industries;

(d) Dust generated and thrown to general atmosphere by various industries such as cement plants, ore / stone crushing units, mining industries due to rock drilling & movements of mining machineries & blasting etc.;

(e) Waste deposition for landfills which generate methane;

(f) Toxic / germ / noxious gasses and fumes generated from military activities and explosives blasting in mines.

2.0. Mechanism of Adverse Impact of Smoke Pollutant – The main sources of smoke pollutants in urban areas are Petrol / Diesel driven motor vehicles, Fuel combustion in stationary sources including residential, commercial and industrial heating / cooling system and coal-burning power plants etc.

Petrol / Diesel driven motor vehicles produce high levels of Carbon Dioxide (CO2) / Carbon Monoxide (CO), major source of Hydrocarbon (HC) and Nitrogen oxides (NOx). Fuel combustion in stationary sources is the dominant source of Carbon Dioxide (CO2) and Sulfur Dioxide (SO2).

Carbon Dioxide (CO2) – This is one of the major gas pollutants in the atmosphere. Major sources of CO2 are due to burning of fossil fuels and deforestation. Industrially developed countries like USA, Russia etc., account for more than 65% of CO2 emission. Less developed countries with 80% of world’s population responsible for about 35% of CO2 emission. Due to high growth reported from less developed countries in last decade, it is estimated that, the Carbon dioxide emissions may rise from these areas and by 2020 their contribution may become 50%. It has also been seen that, Carbon dioxide emissions are rising by 4% annually.

As ocean water contain about 60 times more CO2 than atmosphere; CO2 released by the industry leads to disturbance of equilibrium of concentration of CO2 in the system. In such a scenario, the oceans would absorb more and more CO2 and atmosphere would also remain excess of CO2. As water warms, ocean’s ability to absorb CO2 is reduced. CO2 is a good transmitter of sunlight, but partially restricts infrared radiation going back from the earth into space. This produces the so-called “Greenhouse Effect” that prevents a drastic cooling of the Earth during the night. This so-called “Greenhouse Effect” is responsible for GLOBAL WARMING. Currently Carbon Dioxide is responsible for major portion of the global warming trend.

Nitrogen oxides (NOx) – They come mainly from nitrogen based fertilizers, deforestation, and biomass burning. Nitrogen oxides contribute mostly as atmospheric contaminants. These gases are responsible in the formation of both acid precipitation and photochemical smog and causes nitrogen loading. These gases have a role in reducing stratospheric ozone.

Sulfur Dioxide (SO2) – Sulfur dioxide is produced by combustion of sulfur-containing fuels, such as coal and fuel oils. SO2 also produced in the process of producing Sulfuric Acid and in metallurgical process involving ores that contain sulfur. Sulfur oxides can injure man, plants and materials. As emissions of sulfur dioxide and nitric oxide from stationary sources are transported long distances by winds, they form secondary pollutants such as nitrogen dioxide, nitric acid vapor, and droplets containing solutions of sulfuric acid, sulfate, and nitrate salts. These chemicals descend to the earth’s surface in wet form as rain or snow and in dry form as a gases fog, dew, or solid particles. This is known as acid deposition or acid rain.

Choloroflurocarbons (CFCs) – Chlorofluorocarbons, also known as Freons, are greenhouse gases that contribute to global warming. CFCs are responsible for lowering the average concentration of ozone in the stratosphere.

Smog – Smog is the result from the irradiation by sunlight of hydrocarbons caused primarily by unburned gasoline emitted by automobiles and other combustion sources. Smog is created by burning coal and heavy oil that contain mostly sulfur impurities.

3.0. Mechanism of air pollution by particulate matters (Fine and Coarse Dust particles) – ‘Fine particles’ are less than 2.5 micron in size and require electron microscope for detection, however, they are much larger than the molecules of Ozone etc., and other gaseous pollutants, which are thousands times smaller and cannot be seen through even electron microscope.

Fine particles are formed by the condensation of molecules into solid or liquid droplets, whereas larger particles are mostly formed by mechanical breakdown of material or crushing of minerals. ‘Coarse particles’ are between 2.5 to 10 micron size, and cannot penetrate as readily as of Fine particle; however, it has been seen these are responsible for serious health hazards. The severity of the health hazards vary with the chemical nature of the particles.

The inhalation of particles has been linked with illness and deaths from heart and lung disease as a result of both short- and long-term exposures. People with heart and lung disease may experience chest pain, shortness of breath, fatigue etc., when exposed to particulate-matter pollutants. Inhalation of particulate matter can increase susceptibility to respiratory infections such as Asthma, Chronic Bronchitis. The general medical term given for such lung diseases is ‘Pneumoconiosis’.

Emissions from diesel-fuel combustion in vehicles / engines / equipments; Dusts from cement plants, power plants, chemical plants, mines are a special problem, specially for those individuals breathing in close proximity to such atmosphere. Cars, trucks and off-road engines emit more than half a million tones of diesel particulate matter per year.

3.1. Controlling Airborne Particulate Matters – Airborne particulate matters (PM) emissions can be minimized by pollution prevention and emission control measures. Prevention, which is frequently more cost-effective than control, should be emphasized. Special attention should be given to mitigate the effects, where toxics associated with particulate emissions may pose a significant environmental risk.

Measures such as improved process design, operation, maintenance, housekeeping, and other management practices can reduce emissions. By improving combustion efficiency in Diesel engines, generation of particulate matters can be significantly reduced. Proper fuel-firing practices and combustion zone configuration, along with an adequate amount of excess air, can achieve lower PICs (products of incomplete combustion). Few following steps should be adhered to control PM:

a. Choosing cleaner fuels – Natural gas used as fuel emits negligible amounts of particulate matter.

b. Low-ash fossil fuels contain less noncombustible, ash-forming mineral matter and thus generate lower levels of particulate emissions.

c. Reduction of ash by coal cleaning reduces the generation of ash and Particulate Matter (PM) emissions by up to 40%.

d. The use of more efficient technologies or process changes can reduce PIC emissions.

e. Advanced coal combustion technologies such as coal gasification and fluidized-bed combustion are examples of cleaner processes that may lower PICs by approximately 10%.

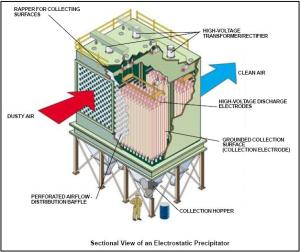

f. A variety of particulate removal technologies, are available – these are (a) Inertial or impingement separators, (b) Electrostatic precipitators (ESPs) , (c) Filters and dust collectors (baghouses), (d) Wet scrubbers that rely on a liquid spray to remove dust particles from a gas stream.

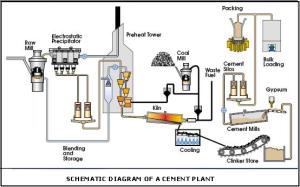

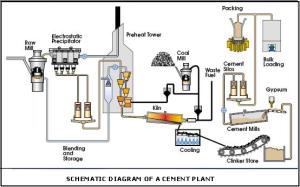

4.0. Dust in cement industry – Its prevention and collection enhances environment standard : The manufacturing of cement involves mining; crushing and grinding of raw materials (mostly limestone and clay); calcinating the material in rotary kiln; cooling the resulting clinker; mixing the clinker with Gypsum; and milling, storing and bagging the finished cement. The cement manufacturing process generates lot of dust, which is captured and recycled to the process. Gasses from clinker cooler are used as secondary combustion air. The process, using pre-heaters and pre-calciners, is both economically and environmentally preferable to wet process because of techno-economic advantages of the energy saving dry system over wet. Certain other solids such as pulverized fly ash from power plants, slag, roasted pyrite residue and foundry sand can be used as additives to prepare blended cement.

a. Dust generation:Generation of fine particulates and dust are inherent in the process; but most are recovered and recycled. The sources of dust emission include clinker cooler, crushers, grinders and material-handling equipment's. Material-handling operations such as conveyors result in fugitive dust emission.

b. Prevention and control of dust: The priority in the cement industry is to minimize the increase in ambient particulate levels by reducing the mass load emitted from the stacks, from fugitive emissions, and from other sources. Collection and recycling of dust in the kiln gases in required to improve the efficiency of the operation and to reduce atmospheric emissions. Units that are well designed, well operated, and well maintained can normally achieve generation of less than 0.2 kilograms of dust per metric tonne (kg /t) of clinker, using dust recovery systems. For control of fugitive dust (a) ventilation systems should be used in conjunction with hoods and enclosures covering transfer points and conveyors; (b) Drop distances should be minimized by the use of adjustable conveyors; (c) Dusty areas such as roads should be wetted down to reduce dust generation; (d) Appropriate stormwater and runoff control systems should be provided to minimize the quantities of suspended material carried off site.

c. Mechanical systems for controlling dust: Several mechanical equipments are used in cement manufacturing plant to control / collect dust. These are:

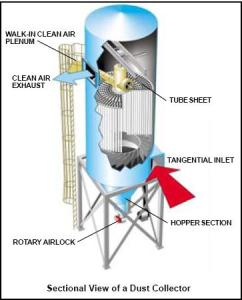

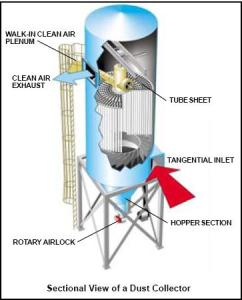

(i) Dust collector - A dust collector (bag house) is a typically low strength enclosure that separates dust from a gas stream by passing the gas through a media filter. The dust is collected on either the inside or the outside of the filter. A pulse of air or mechanical vibration removes the layer of dust from the filter. This type of filter is typically efficient when particle sizes are in the 0.01 to 20 micron range.

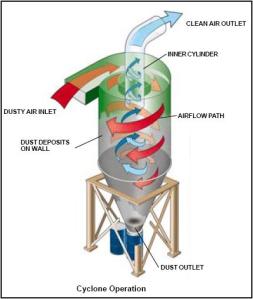

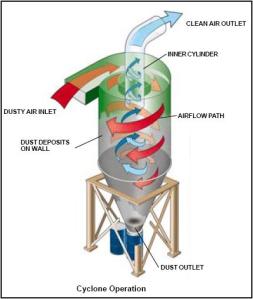

(ii) Cyclone - Dust laden gas enters the chamber from a tangential direction at the outer wall of the device, forming a vortex as it swirls within the chamber. The larger articulates, because of their greater inertia, move outward and are forced against the chamber wall. Slowed by friction with the wall surface, they then slide down the wall into a conical dust hopper at the bottom of the cyclone. The cleaned air swirls upward in a narrower spiral through an inner cylinder and emerges from an outlet at the top. Accumulated particulate dust is deposited into a hopper, dust bin or screw conveyor at the base of the collector. Cyclones are typically used as pre-cleaners and are followed by more efficient air-cleaning equipment such as electrostatic precipitators and bag houses.

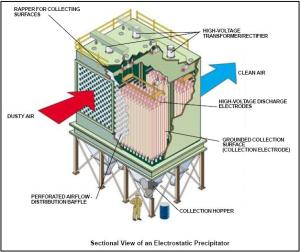

(iii) Electrostatic Precipitator - In an electrostatic precipitator, particles suspended in the air stream are given an electric charge as they enter the unit and are then removed by the influence of an electric field. A high DC voltage (as much as 100,000 volts) is applied to the discharge electrodes to charge the particles, which then are attracted to oppositely charged collection electrodes, on which they become trapped. An electrostatic precipitator can remove particulates as small as 1 μm (0.00004 inch) with an efficiency exceeding 99 percent.

5.0. Dust in Coal Handling Plant (CHP) and its control systems:Thermal power plants (coal-fired power plants) use coal as their fuel. To handle the coal, each power station is equipped with a coal handling plant. The coal has to be sized, processed, and handled which should be done effectively and efficiently. The major factor which reduces the staff efficiency in operation of coal handling plant is the working environment i.e. a dusty atmosphere and condition. Lots of care is always needed to reduce dust emission. In developing countries, all most all systems used in power station coal handling plants are wet dust suppression systems.

5.1. After dust is formed, control systems are used to reduce dust emissions. Although installing a dust control system does not assure total prevention of dust emissions, a well-designed dust control system can protect workers and often provide other benefits, such as (a) Preventing or reducing risk of dust explosion or fire; (b) Increasing visibility and reducing probability of accidents; (c) Preventing unpleasant odors; (d) Reducing cleanup and maintenance costs; (e) Reducing equipment wear, especially for components such as bearings and pulleys on which fine dust can cause a “grinding” effect and increase wear or abrasion rates; (f) Increasing worker morale and productivity; (f) Assuring continuous compliance with existing health regulations. In addition, proper planning, design, installation, operation, and maintenance are essential for an efficient, cost-effective, and reliable dust control system.

5.2. There are two basic types of dust control systems currently used in minerals processing operations are:

(a) Dust collection system - Dust collection systems use ventilation principles to capture the dust-filled air-stream and carry it away from the source through ductwork to the collector. A typical dust collection system consists of four major components, such as (1) An exhaust hood to capture dust emissions at the source; (2) Ductwork to transport the captured dust to a dust collector; (3) A dust collector to remove the dust from the air; (4) A fan and motor to provide the necessary exhaust volume and energy.

(b) Wet dust suppression system - Wet dust suppression techniques use water sprays to wet the material so that it generates less dust. There are two different types of wet dust suppression:

(i) wets the dust before it is airborne (surface wetting) and

(ii) wets the dust after it becomes airborne. In many cases surfactants or chemical foams are often added to the water into these systems in order to improve performance.

A water spray with surfactant means that a surfactant has been added to the water in order to lower the surface tension of the water droplets and allow these droplets to spread further over the material and also to allow deeper penetration into the material.

i. Surface wetting system: The principle behind surface wetting is the idea that dust will not even be given a chance to form and become airborne. With this method, effective wetting of the material can take place by static spreading (wetting material while it is stationary) and dynamic spreading (wetting material while it is moving). For static wetting, more effective dust suppression arises by increasing the surface coverage by either reducing the droplet diameter or its contact angle. For dynamic spreading, more factors come into play such as the surface tension of the liquid, the droplet diameter, the size of the material being suppressed, and the droplet impact velocity.

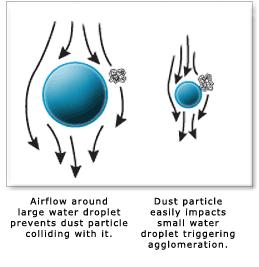

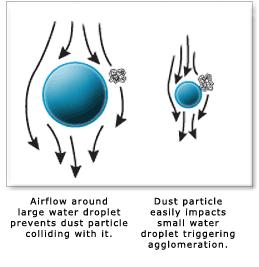

ii. Airborne dust capture system -Airborne dust capture systems may also use a water-spray technique; however, airborne dust particles are sprayed with atomized water. When the dust particles collide with the water droplets, agglomerates are formed. These agglomerates become too heavy to remain airborne and settle. Airborne dust wet suppression systems work on the principle of spraying very small water droplets into airborne dust. When the small droplets collide with the airborne dust particles, they stick to each other and fall out of the air to the ground. Research showed that, if a sufficient number of water droplets of approximately the same size as the dust particles could be produced, the possibility of collision between the two would be extremely high. It was also determined that if the droplet exceeded the size of the dust particle, there was little probability of impact and the desired precipitation. Instead, the dust particle would move around the droplet.

5.3. System Efficiency:

Over the years, water sprays has established the following facts:

(a) For a given spray nozzle, the collection efficiency for small dust particles increases as the pressure increases;

(b) At a given pressure, the efficiency increases as the nozzle design is changed so as to produce smaller droplets. The efficiency of spray dust capture increases by increasing the number of smaller sized spray droplets per unit volume of water utilized and by optimizing the energy transfer of spray droplets with the dust-laden air.

5.4. Sophisticated system like ‘Ultrasonic Dust Suppression’ systems uses water and compressed air to produce micron sized droplets that are able to suppress respirable dust without adding any detectable moisture to the process. Ideal for spray curtains to contain dust within hoppers. The advantages of using Ultrasonic Atomizing Systems for dust suppression can therefore be summarized as: (a) reduced health hazards; (b) decrease in atmospheric pollution; (c) improved working conditions; (d) efficient operation with minimum use of water.

6.0. Air pollution control devices / equipments for industries, in general

The commonly used equipment's / process for control of dust in various industries are (a) Mechanical dust collectors in the form of dust cyclones; (b) Electrostatic precipitators – both dry and wet system; (c) particulate scrubbers; (d) Water sprayer at dust generation points; (e) proper ventilation system and (f) various monitoring devices to know the concentration of dust in general body of air.

The common equipment's / process used for control of toxic / flue gases are the (a) process of desulphurisation; (b) process of denitrification; (c) Gas conditioning etc. and (d) various monitoring devices to know the efficacy of the systems used.

7.0. Occupational Hazards / diseases due to expose in dusty and polluted air:

There are certain diseases which are related to one’s occupation. These are caused by constant use of certain substances that sneak into air and then enter our body.

(i) Silicosis

(Silico-tuberculosis) occurs due to inhalation of free silica, or SiO2 (Silicon dioxide), while mining or working in industries related to pottery, ceramic, glass, building and construction work. The workers get chronic cough and pain in the chest. Silicosis treatment is extremely limited considering a lack of cure for the disease. However, like all occupational respiratory ailments, it is 100% preventable if exposure is minimized.

(ii) Asbestosis is caused by asbestos, which is used in making ceilings. It is also considered as cancer causing agent. Pathogenesis of the disease is characterized as progressive and irreversible, leading to subsequent respiratory disability. In severe cases, asbestosis results in death from pulmonary hypertension and cardiac failure.

(iii) Byssinosis, also referred to as brown lung disease, is an occupational respiratory disorder characterized by the narrowing of pulmonary airways. It is a disabling lung disease, which is marked by chronic cough and chronic bronchitis due to inhalation of cotton fibers over a long period of time.

(iv) Coal worker’s Pneumoconiosis

occurs due to inhalation of coal dust from coal mining industry. Also referred to as black lung disease. The workers suffer from lung problems. Apart from asbestosis, black lung disease is the most frequently occurring type of pneumoconiosis . In terms of disease pathogenesis, a time delay of nearly a decade or more occurs between exposure and disease onset.

7.1. Preventive Measures

The most successful tool of prevention of respiratory diseases from industrial dust is to minimize exposure. However, this is not a practical approach from the perspective of industries such as mining, construction/demolition, refining/manufacturing/processing, where industrial dust is an unavoidable byproduct. In such cases, industries must implement a stringent safety protocol that effectively curtails exposure to potentially hazardous dust sources. National Institute for Occupational Safety and Health (NIOSH) recommended precautionary measures to reduce exposure to a variety of industrial dust types.

1. Recognize when industrial dust may be generated and plan ahead to eliminate or control the dust at the source. Awareness and planning are keys to prevention of silicosis.

2. Do not use silica sand or other substances containing more than 1% crystalline silica as abrasive blasting materials. Substitute less hazardous materials.

3. Use engineering controls and containment methods such as blast-cleaning machines and cabinets, wet drilling, or wet sawing of silica-containing materials to control the hazard and protect adjacent workers from exposure.

4. Routinely maintain dust control systems to keep them in good working order.

5. Practice good personal hygiene to avoid unnecessary exposure to other worksite contaminants such as lead.

6. Wear disposable or washable protective clothes at the worksite.

7. Shower (if possible) and change into clean clothes before leaving the worksite to prevent contamination of cars, homes, and other work areas.

8. Conduct air monitoring to measure worker exposures and ensure that controls are providing adequate protection for workers.

9. Use adequate respiratory protection when source controls cannot keep silica exposures below the designated limit.

10. Provide periodic medical examinations for all workers who may be exposed to respirable crystalline silica.

11. Post warning signs to mark the boundaries of work areas contaminated with respirable crystalline silica.

12 Provide workers with training that includes information about health effects, work practices, and protective equipment for respirable crystalline silica.

13. Report all cases of silicosis to Federal / State health departments.

8.0. Preventing damaging effects of air and dust pollution

The prevention of air pollution is world wide concern. There have been many investigations into what causes air pollution and the exact methods that work best in the prevention of air pollution. Through the use of many different methods air pollution is becoming easier to control. It is only through various measures, though, that the prevention of air pollution is possible. The government plays a very important role in prevention of air pollution. It is through government regulations that industries are forced to reduce their air pollution and new developments in technology are created to help everyone do their part in the prevention of air pollution. The government also helps by continuously making regulations stricter and enforcing new regulations that help to combat any new found source of air pollution.

In many countries in the world, steps are being taken to stop the damage to our environment from air pollution. Scientific groups study the damaging effects on plant, animal and human life. Legislative bodies write laws to control emissions. Educators in schools and universities teach students, beginning at very young ages, about the effects of air pollution. The first step to solving air pollution is assessment. Researchers have investigated outdoor air pollution and have developed standards for measuring the type and amount of some serious air pollutants.

Scientists must then determine how much exposure to pollutants is harmful. Once exposure levels have been set, steps can be undertaken to reduce exposure to air pollution. These can be accomplished by regulation of man-made pollution through legislation. Many countries have set controls on pollution emissions for transportation vehicles and industry. This is usually done to through a variety of coordinating agencies which monitor the air and the environment.

In the prevention of air pollution it is important to understand about indoor air pollution. Indoor air pollution may seem like an individual concern, but it actually is not just something to worry about in your own home. Indoor air pollution contributes to outdoor air pollution. Prevention is another key to controlling air pollution. The regulatory agencies mentioned above play an essential role in reducing and preventing air pollution in the environment. In addition, it is possible to prevent many types of air pollution that are not regulated through personal, careful attention to our interactions with the environment. One of the most dangerous indoor air pollutants is cigarette smoke. Restricting smoking is an important key to a healthier environment. Legislation to control smoking is in effect in some locations, but personal exposure should be monitored and limited wherever possible.

9.0. Conclusion

Air pollution prevention efforts of companies have generally focused on both source and waste reduction, and on reuse and recycling. Preventing air pollution within a company’s manufacturing processes remains the key approach. Cleaning and processing, switch to non-polluting technologies and materials, reduced generation of waste water, converting hazardous by-products to non-threatening forms, etc. have been attempted in this regard. Indirect air pollution prevention measures by companies also cover transportation. Examples of such measures include: providing company transportation to employees; offering commuting information and selling public transit passes; and encouraging employees to carpool and use public transportation. Companies have also initiated successful programmes such as the use of bicycles to commute to work, telecomuting, and work-at-home etc. to reduce pollution due to commuting.

It should be noted that, only through the efforts of scientists, business leaders, legislators, and individuals can we reduce the amount of air pollution on the planet. This challenge must be met by all of us in order to assure that a healthy environment exist for ourselves and our children.